POD Analysis of Turbulent Pipe Flow

M. Raba

Created: 2025-10-06 Mon 04:24

Background and Motivation

Literature Review

- Simple geometry, yet rich in turbulent dynamics

- Ideal for studying rotation-induced turbulence suppression

- Relevant to aerospace, combustion, and industrial flows

- Rotation reduces skin friction and pressure loss

- Experiments (e.g., White 1964, Kikuyama et al. 1983) showed relaminarization at high rotation rates

- Limited DNS studies at moderate-to-high Reynolds numbers

- RANS/LES models struggle to capture suppression mechanisms

- Use DNS to quantify turbulence suppression

- Apply POD to identify dominant coherent structures

- Provide benchmark data for turbulence model validation

DNS Turbulent Model

- Viscous terms: BDF3 (implicit)

- Nonlinear terms: Explicit extrapolation (3rd order)

- Radial: 0.14–4.4 (Re = 5300), 0.16–4.7 (Re = 11,700)

- Azimuthal: 1.5–5.0

- Streamwise: 3.0–9.9

Background: Rotating Pipe Flow & Relaminarization

Scientific Context

- Rotating pipe flow is a canonical system for studying flow stabilization and relaminarization.

- Rotation modifies turbulence production and redistributes momentum through Coriolis and centrifugal effects.

- Relaminarization occurs when rotation suppresses the near-wall turbulence regeneration cycle.

Key Phenomena

- Competition between destabilizing wall shear and stabilizing radial pressure gradients.

- Reduction in Reynolds stresses and near-wall streaks at high rotation rates.

- Relaminarized or quasi-laminar states can persist at high Reynolds numbers.

DNS, Theory, and Modal Decomposition

DNS and Analytical Foundations

- DNS captures relaminarization at Re = 10⁴–10⁵ under rotation.

- Scaling and symmetry analyses (Oberlack, 1999; 2001) relate turbulence structure to invariants.

- Hellström et al. (2017) provide reproducible experimental and DNS methodology for relaminarization.

Modal Analysis (POD)

- Proper Orthogonal Decomposition (POD) identifies energy-dominant coherent structures.

- Developed by Lumley (1967); extended by Taira et al. (2017) for complex turbulent systems.

- Recent studies (Brehm 2019; Ashton 2019) combine DNS and POD for energy transfer diagnostics.

Control & Transition Mechanisms

Mechanistic Understanding

- Rotation alters the balance of production and dissipation terms in the turbulent kinetic energy budget.

- Flow control studies show relaminarization through imposed swirl or wall rotation.

- Experimental relaminarization occurs by suppression of near-wall vortices and streak breakdown.

Recent Advances

- Kühnen et al. (2014, 2018) demonstrated full relaminarization through wall rotation and suction control.

- These results motivate DNS-based exploration of transient energy transfer and POD modal evolution.

- Ongoing studies bridge classical rotation control and modern data-driven modal analysis.

Method Spectral Element Direct Numerical Simulation (DNS)

Slide 1: Introduction

Background

- Transition and relaminarization in rotating pipe flows depend on rotation rate and Reynolds number.

- Relaminarization can occur when imposed swirl suppresses near-wall turbulence production.

- Applications: rotating heat exchangers, turbomachinery, compact fluid systems.

Governing Equations

\begin{align} \nabla \cdot \mathbf{u} &= 0, \\ \frac{\partial \mathbf{u}}{\partial t} + (\mathbf{u}\cdot\nabla)\mathbf{u} &= -\frac{1}{\rho}\nabla p + \nu \nabla^2 \mathbf{u} - 2 \boldsymbol{\Omega}\times\mathbf{u} \end{align}References: Alfredsson & Persson (1989)[1], Johnston et al. (1972)[2]

Slide 2: Spectral Element Method (DNS)

Simulation Setup

- Circular pipe: D=1, L=12D

- Re = 5300, 12700, non-slip wall

- Legendre basis, polynomial order 6

- Non-uniform mesh finer near wall to capture Kolmogorov/Taylor scales

Navier-Stokes in Cylindrical Coordinates

\begin{align} \frac{\partial w}{\partial t} + w \frac{\partial w}{\partial r} + \frac{v}{r} \frac{\partial w}{\partial \theta} + u \frac{\partial w}{\partial x} - \frac{v^2}{r} &= -\frac{1}{\rho} \frac{\partial p}{\partial r} + \nu \left(\mathcal{D} w - \frac{w}{r^2} - \frac{2}{r^2}\frac{\partial v}{\partial \theta} \right) - 2\Omega v \\ \frac{\partial v}{\partial t} + w \frac{\partial v}{\partial r} + \frac{vw}{r} + \frac{v}{r} \frac{\partial v}{\partial \theta} + u \frac{\partial v}{\partial x} &= -\frac{1}{\rho r} \frac{\partial p}{\partial \theta} + \nu \left(\mathcal{D} v - \frac{v}{r^2} + \frac{2}{r^2}\frac{\partial w}{\partial \theta} \right) + 2\Omega w \\ \frac{\partial u}{\partial t} + w \frac{\partial u}{\partial r} + \frac{v}{r} \frac{\partial u}{\partial \theta} + u \frac{\partial u}{\partial x} &= -\frac{1}{\rho} \frac{\partial p}{\partial x} + \nu \mathcal{D} u \end{align}References: Kundu (2015)[3], Hellström et al. (2017)[4]

Slide 3: Mesh and Simulation Details

Mesh Details

- Non-uniform grid denser near walls

- Grid spacings (y+) for streamwise extent of 15D

- Example: Re=5300, Δr⁺=0.14–4, Δθ⁺=1.5–4.5, Δz⁺=3–9.9

Boundary Conditions

\begin{align} u_r(R) &= 0, \\ u_\theta(R) &= \Omega R, \\ u_x(R) &= 0 \end{align}Rotation vector: Ω = Ω e_k; smooth wall, incompressible flow

[2] Johnston et al., 1972.

[3] Kundu, 2015, Fluid Mechanics.

[4] Hellström et al., 2017, J. Fluid Mech. 829:164–188.

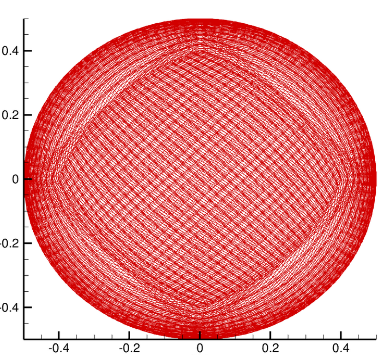

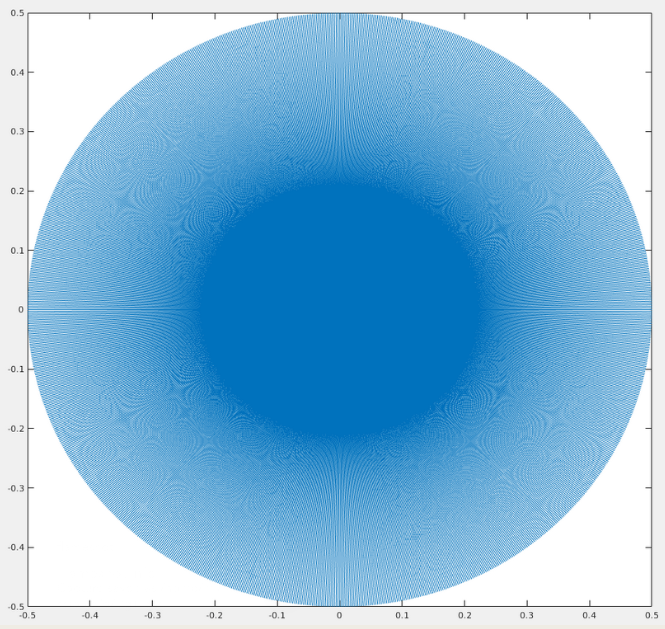

DNS Mesh

Simulation Domain

- Circular pipe, D = 1, L = 12D

- Reynolds numbers: 5300, 12700

- Non-slip at walls, periodic at inlet/outlet

- Spectral element method: Legendre basis, order l = 6

Governing Equations

\begin{align} \nabla \cdot \boldsymbol{u} &= 0 \\ \frac{\partial \boldsymbol{u}}{\partial t}+ (\boldsymbol{u}\cdot\nabla)\boldsymbol{u} &= -\nabla p + \frac{1}{Re} \nabla^2 \boldsymbol{u} \end{align}Mesh Images

Non-uniform mesh (finer near walls)

Uniform, interpolated mesh for POD analysis

Grid Spacing and Boundary Conditions

Grid Spacings (y⁺ units)

| Re | Δr⁺ / Δθ⁺ / Δz⁺ | N Δt × 10⁶ |

|---|---|---|

| 5,300 | 0.14–4 / 1.5–4.5 / 3–9.9 | 20 |

| 11,700 | 0.15–4.5 / 1.5–4.8 / 3–10 | 120 |

Boundary Conditions

\begin{align} u_r(R) &= 0, \\ u_\theta(R) &= \Omega R, \\ u_x(R) &= 0 \end{align}Rotation vector: Ω = Ω e_k; smooth wall; incompressible flow

Proper Orthogonal Decomposition

POD Energy Modes

(2.1) Radial eigenvalue problem:

$$ \int S(k, m; r, r') \, \Phi_n(k, m; r') \, r' \, dr' = \lambda_n(k, m) \, \Phi_n(k, m; r) $$(2.2) Cross-correlation tensor:

$$ S(k, m; r, r') = \lim_{\tau \to \infty} \frac{1}{\tau} \int_0^\tau \mathbf{u}(k, m; r, t) \, \mathbf{u}^*(k, m; r', t) \, dt $$(2.3) POD coefficient projection:

$$ \alpha_n(k, m; t) = \int \mathbf{u}(k, m; r, t) \, \Phi_n^*(k, m; r) \, r \, dr $$(2.4) Time-domain eigenvalue problem:

$$ \int R(k, m; t, t') \, \alpha_n(k, m; t') \, dt' = \lambda_n(k, m) \, \alpha_n(k, m; t) $$(2.5) Mode reconstruction:

$$ \int \mathbf{u}^T(k, m; r, t) \, \alpha_n^*(k, m; t) \, dt = \Phi_n^T(k, m; r) \, \lambda_n(k, m) $$(2.6) Conditional mode definition:

$$ \Psi_n(m; \xi, r) = \lim_{\chi \to \infty} \frac{1}{\chi} \int_0^\chi \int_0^\tau \mathbf{u}^T(m; r, x+\xi, t) \, \alpha_n(m; x, t) \, dt \, dx $$FFT / POD Interpretation

Azimuthal FFT:

- Exploits rotational symmetry of the pipe

- Azimuthal mode number m defines spanwise length scale

- Highlights circumferential structure and periodicity

Streamwise FFT:

- Captures axial periodicity and wavelength

- Mode number k relates to streamwise extent of structures

- Useful for identifying repeating patterns like VLSMs

Why FFT?

- Geometry-driven decomposition

- Modes are known a priori due to symmetry

- Accelerates POD convergence

Nature of POD Modes:

- Data-driven: extracted from simulation or experiment

- Ranked by energy content (most energetic first)

- Capture coherent structures across scales

Snapshot POD:

- Assumes separability of space and time

- Reduces computational cost by working in time domain

- Enables modal analysis of large datasets

Complementarity:

- FFT modes reflect geometry

- POD modes reflect physics and energy distribution

- Combined FFT-POD approach enhances interpretability

Proper Orthogonal Decomposition (POD)

POD Overview

- Decomposes turbulent velocity field to a reduced order model (ROM)

- Orthogonal basis captures dominant flow patterns 1

- Snapshot POD faster convergence than classical POD

- Hybrid FFT-POD: Fourier modes in θ, POD in radial direction

Snapshot POD: Hilbert Space

Snapshot POD: Eigenvalue Problem

Direct POD Equation

Temporal Coefficients

Classical POD Form

Correlation Tensor

Time Coefficient

Radial Projections

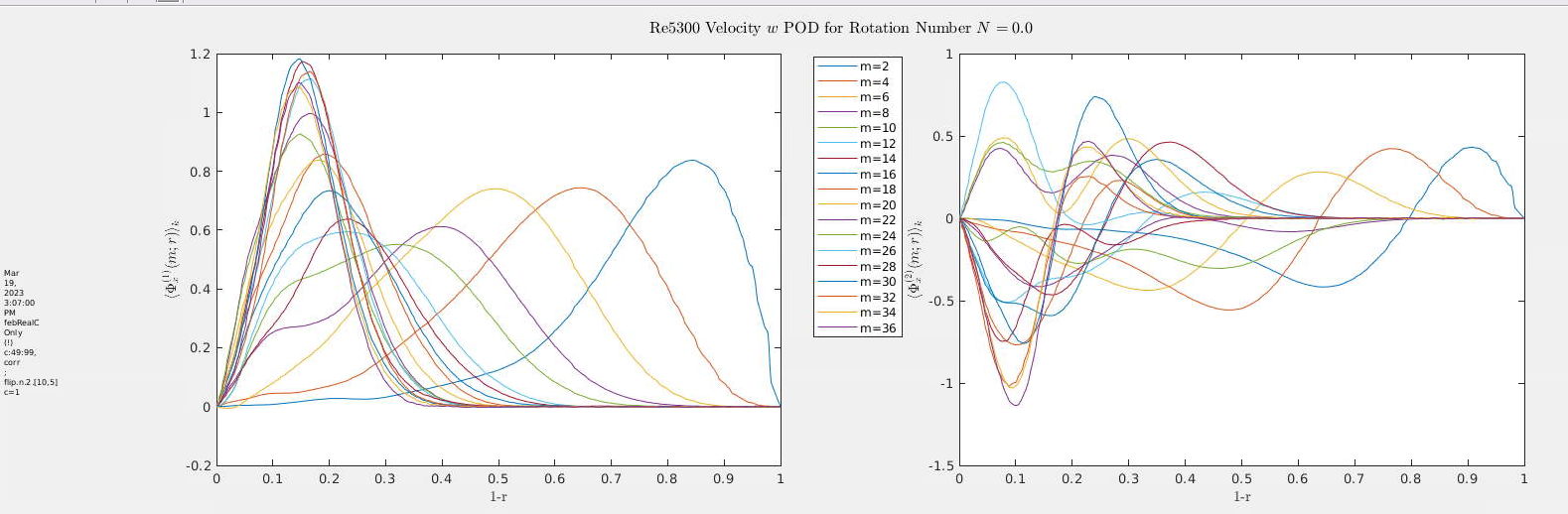

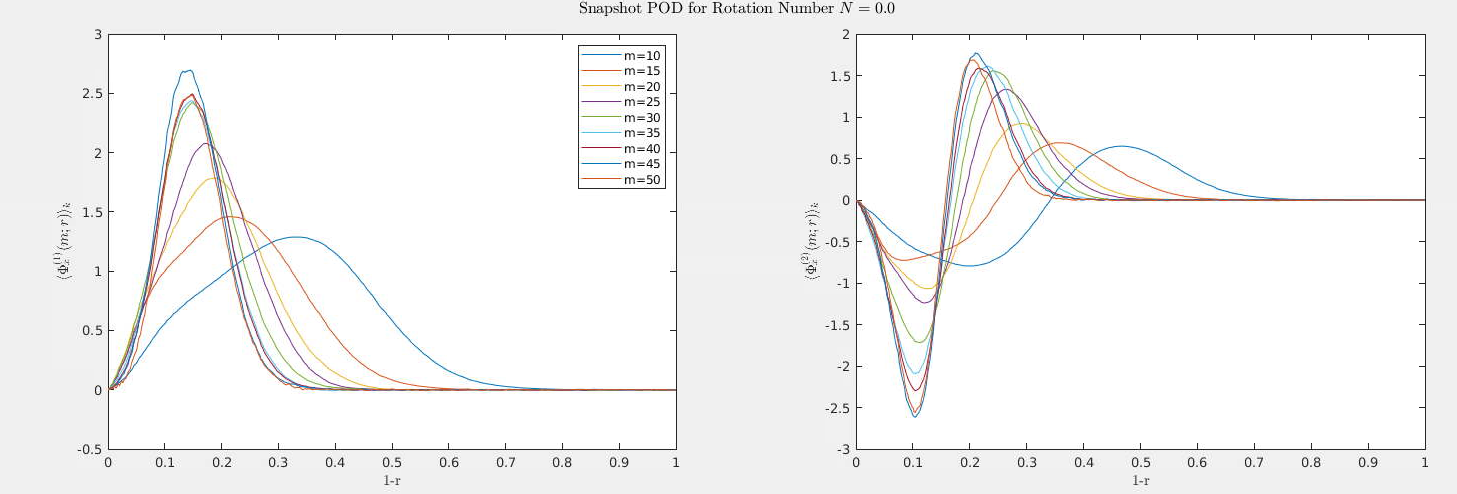

POD Mode Behavior at N = 0

- Rotation Number: N = 0 (non-rotating pipe)

- Flow Regime: Classical turbulent pipe flow

- Azimuthal Modes: m = 2 to 36

- Radial Profiles: Symmetric, peak away from wall

- Conditional Modes: Show coherent structures aligned with streamwise direction

- Interpretation: Near-wall turbulence is strong; structures are well-developed and span the pipe radius

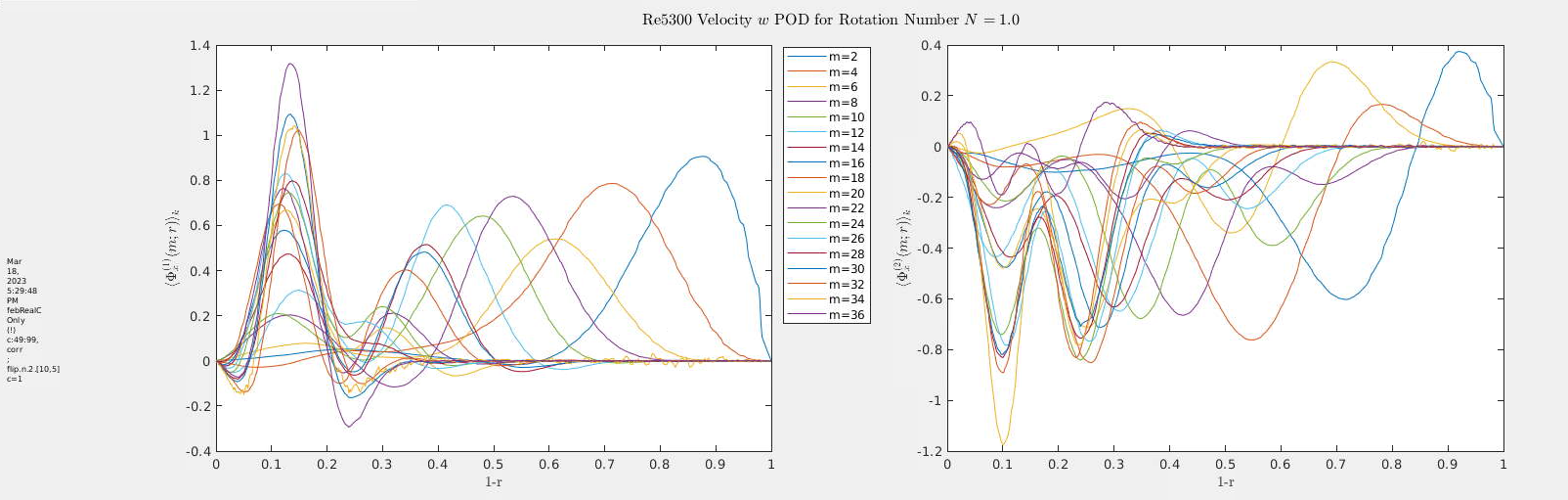

POD Mode Behavior at N = 1

- Rotation Number: N = 1 (moderate rotation)

- Swirl Number: Ratio of azimuthal to axial momentum flux; quantifies rotational intensity

- Flow Regime: Transitional toward relaminarization

- Azimuthal Modes: m = 2 to 36

- Radial Profiles: Begin to shift inward; near-wall peaks flatten

- Azimuthal Structure: Enhanced swirl due to Coriolis effects

- Interpretation: Rotation suppresses near-wall turbulence and redistributes energy toward the core

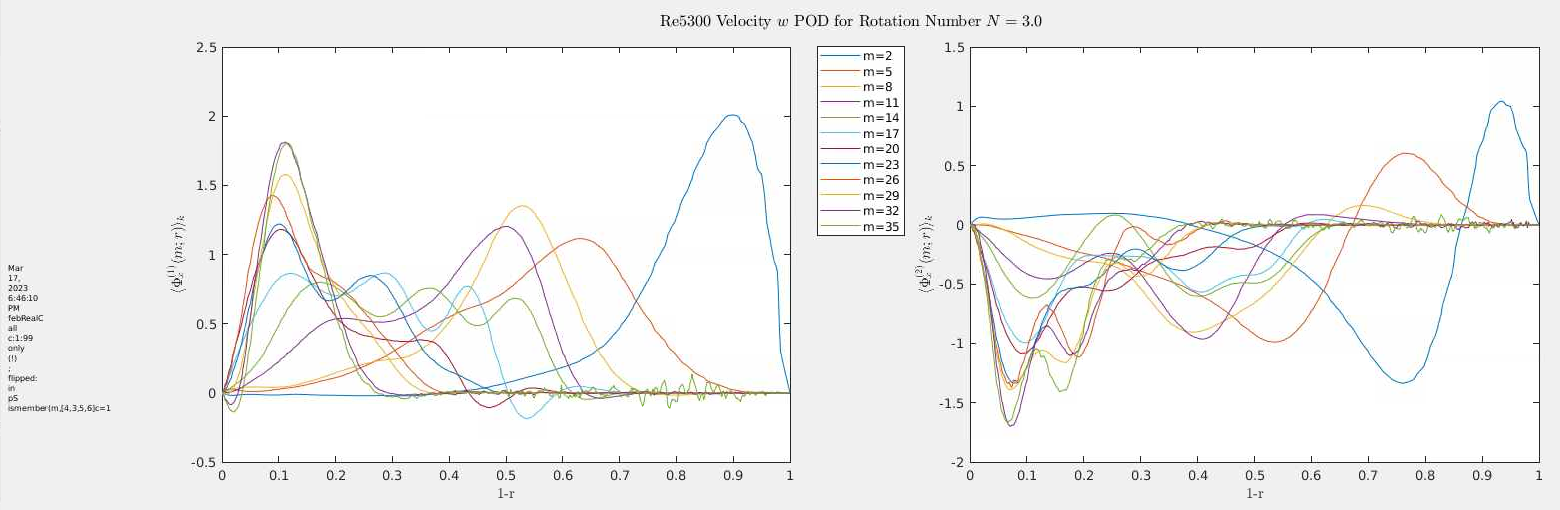

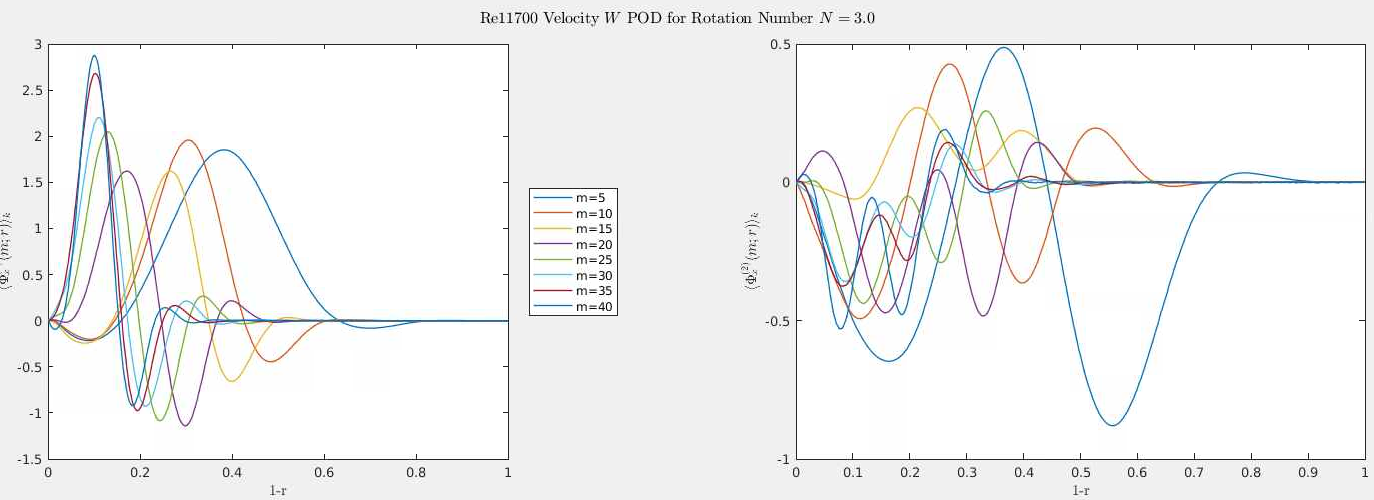

N=3

- Rotation Number: N = 3 (strong rotation)

- Swirl Number: High azimuthal momentum; dominant rotational effects

- Flow Regime: Strong turbulence suppression; approaching relaminarization

- Azimuthal Modes: Energy concentrated in low modes (m = 5–20)

- Radial Profiles: Streamwise structures shift closer to wall; radial structures broaden

- Azimuthal Structure: Reduced wall-normal extent; secondary peaks emerge

- Interpretation: Rotation reorganizes turbulence, suppresses near-wall activity, and enhances core coherence

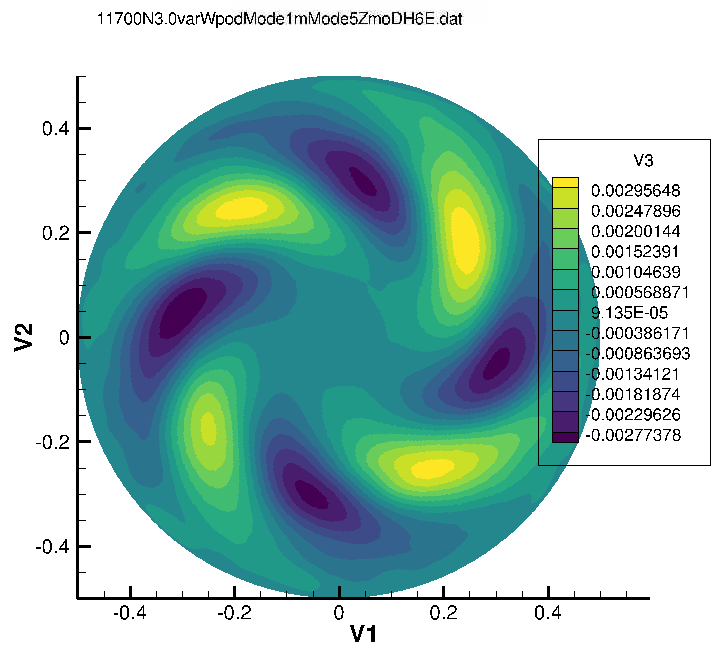

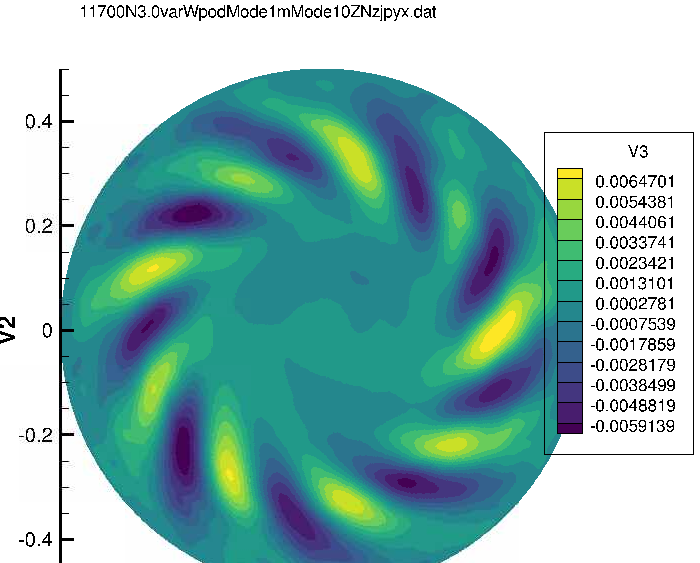

FFT-POD Mode Shapes

Coherent structure with 5-lobed symmetry; strong modal energy concentration.

Finer-scale oscillatory structure; reduced energy per mode compared to m = 5.

Radial POD Modes

Figure 1: \(N=0.0\) Radial POD Azimuthal Modes

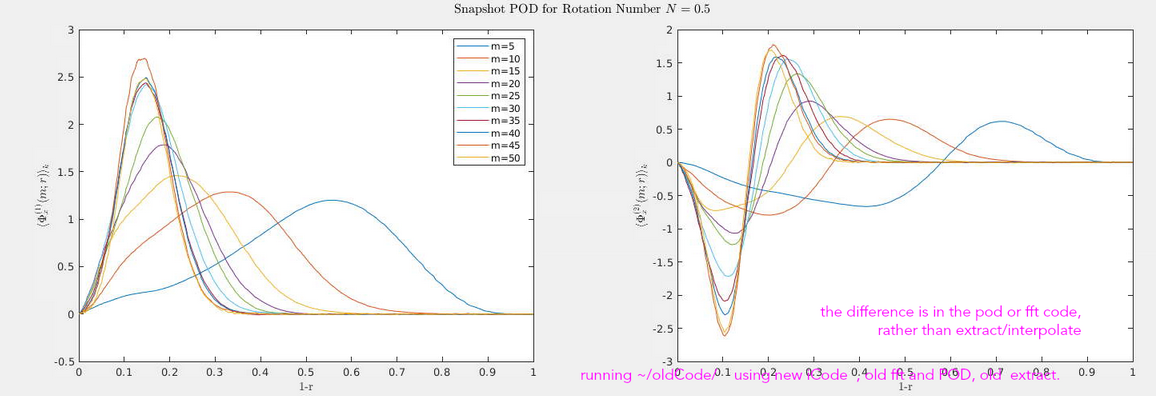

\(N=0.5\)

Figure 2: \(N=0.5\) Radial POD Azimuthal Modes

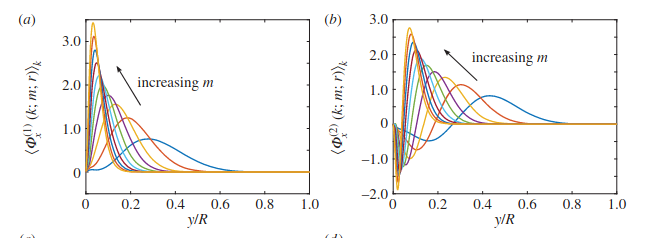

Figure 3: Ref (Hellstrom 2017 Benchmark)

\(N=3\)

Figure 4: \(N=3\) Radial POD Azimuthal Modes

Rotating Pipe POD Results

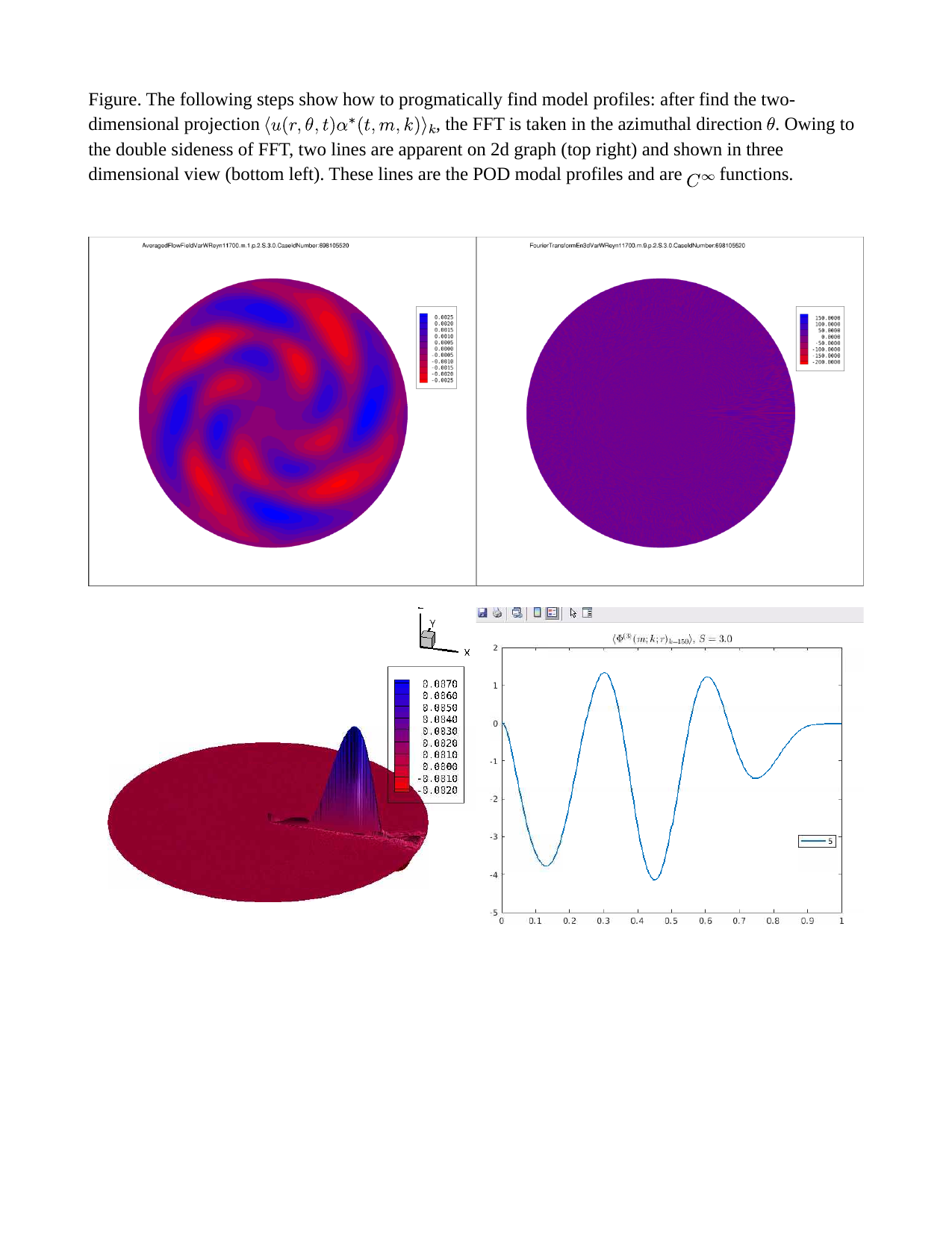

Rotating Pipe POD Results — POD Theory & 2D Projection

POD Modes & 2D Projection

- Azimuthal modes m ∈ [1,30]

- Streamwise-invariant, averaged along x

- Phase-flipped to ensure consistent ±1 orientation

- FFT in θ direction for radial profiles

Radial Modal Profile Equation

2D POD Projection Example

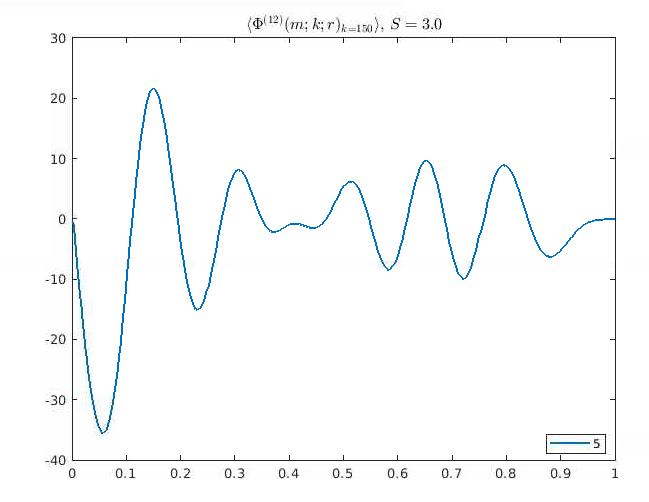

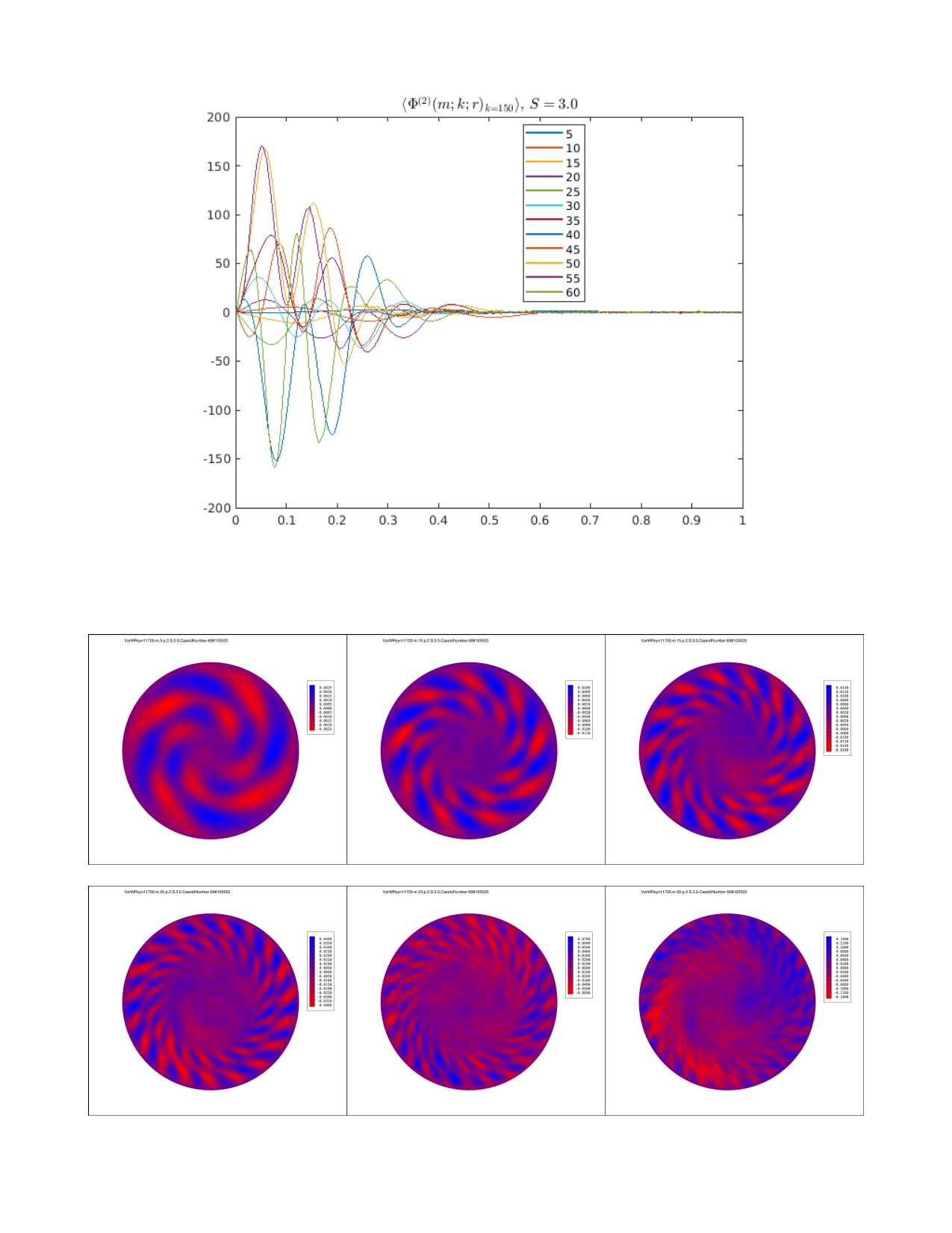

Modal Profile φ²

Streamwise Component φ², S=3.0

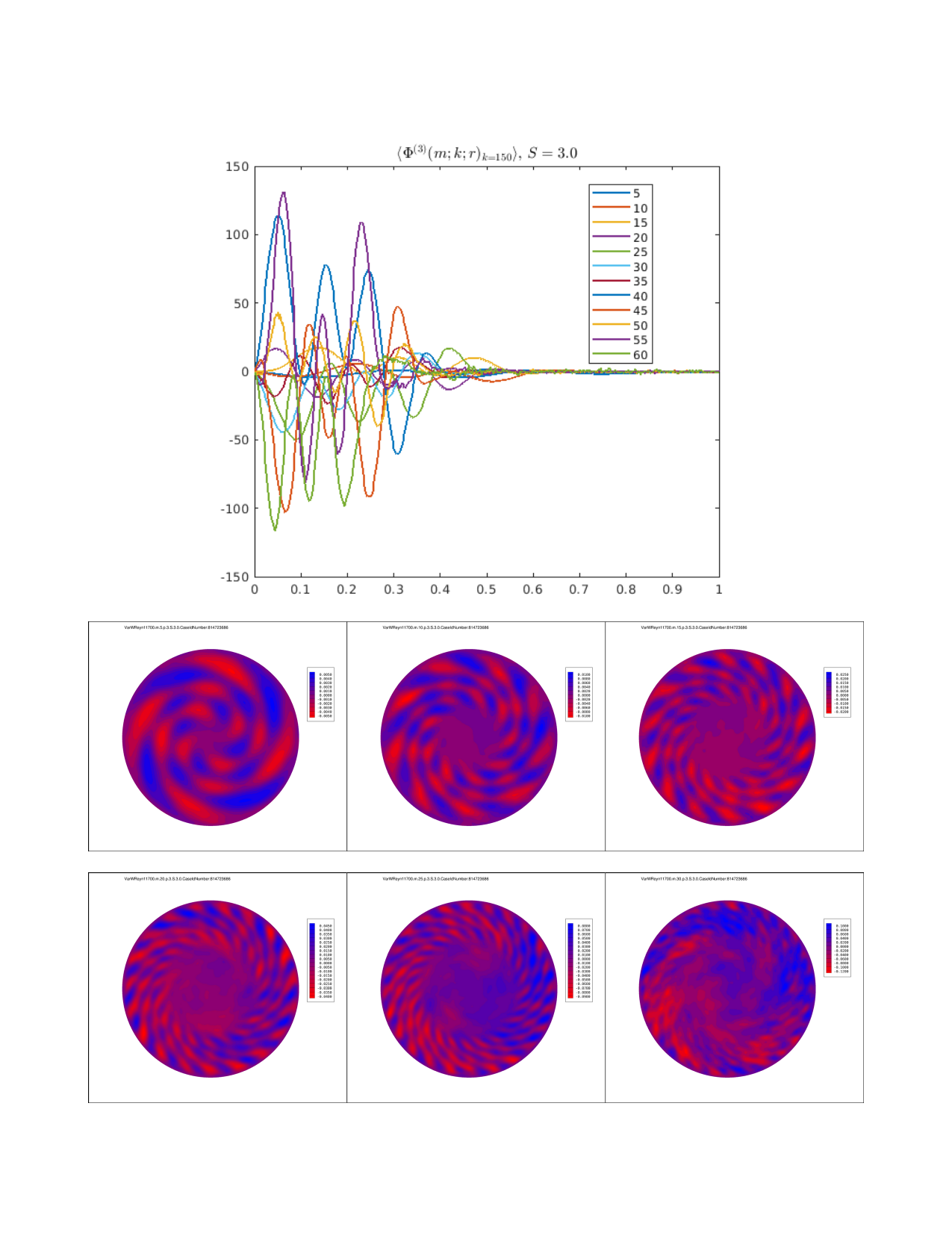

Modal Profile φ³

Streamwise Component φ³, S=3.0

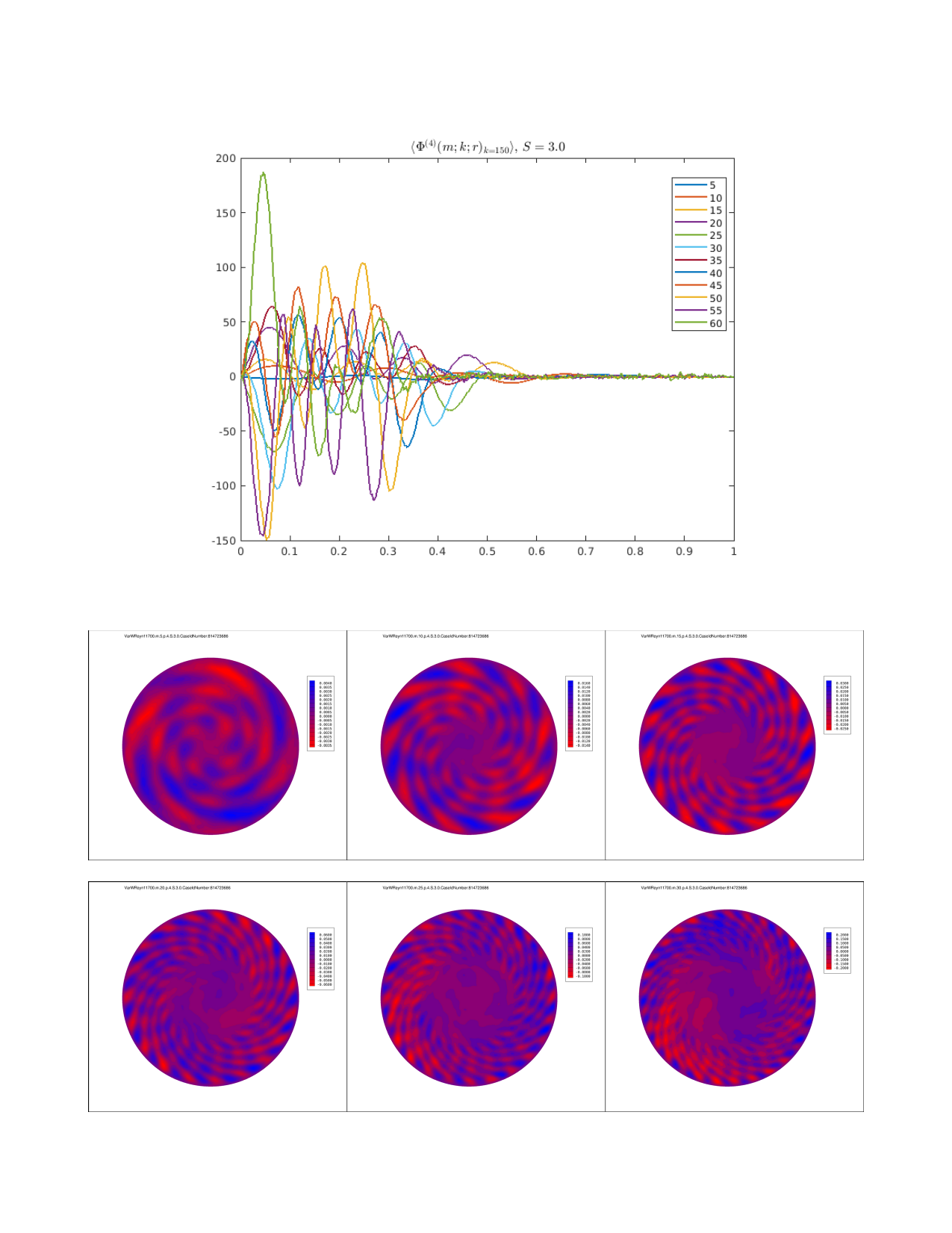

Modal Profile φ⁴

Streamwise Component φ⁴, S=3.0

Derivation of POD

Derivation of POD Projections

Citations

References

-

Hellström, L. H. O. (2017). Relaminarisation of Turbulent Pipe Flow through Oscillatory Forcing. PhD thesis, Princeton University

— Methodology and experimental setup for relaminarization in rotating/oscillatory conditions. -

Kühnen, J., Holtz, E., Hof, B. (2014). Experimental investigation of turbulent drag reduction by wall rotation. J. Fluid Mech., 738:463–487.

— Shows streamwise wall rotation can trigger relaminarization. -

Kühnen, J., Song, B., Scarselli, D., Budanur, N. B., Riedl, M., Willis, A. P., Hof, B. (2018). Destabilizing turbulence in pipe flow. Nature Phys., 14(4):386–390.

— Demonstrated full relaminarization via body forcing. -

Xiao, Y., Peixinho, J. (2019). Experimental investigation of relaminarisation of turbulent flow in a rotating pipe. J. Fluid Mech., 862: R1.

— Full relaminarization achieved through global rotation. -

Czarske, J., Büttner, L., Budinger, M., et al. (2002). Velocity measurements in rotating turbulent pipe flow. Exp. Fluids, 33(1):115–123.

— Laser-Doppler data showing turbulence structure changes under rotation.

-

Johnston, J. P., Halleen, R. M., Lezius, D. K. (1972). Effects of spanwise rotation on the structure of two-dimensional fully developed turbulent channel flow. J. Fluid Mech., 56(3):533–557.

— Classic rotation-induced turbulence suppression study. -

Grundestam, O., Wallin, S., Johansson, A. V. (2008). Direct numerical simulations of rotating turbulent pipe flow. J. Fluid Mech., 598:177–199.

— DNS showing relaminarization trends with rotation rate. -

Facciolo, L., Peixinho, J. (2018). Dynamics of laminar and turbulent flows in rotating pipes. Phys. Rev. Fluids, 3:034603.

— Defines critical rotation numbers for relaminarization. -

Reynolds, O. (1883). An experimental investigation of the circumstances which determine whether the motion of water shall be direct or sinuous. Phil. Trans. R. Soc., 174:935–982.

— Foundational work on laminar–turbulent transition. -

Wu, X., Moin, P. (2008). A direct numerical simulation study on the mean velocity characteristics in turbulent pipe flow. J. Fluid Mech., 608:81–112.

— DNS baseline for assessing relaminarization thresholds.