Anand Model: Theoretical Forumation and Application to Solder Joints

Michael Raba, MSc Candidate at University of Kentucky

Created: 2025-04-20 Sun 20:27

Source Paper

Introduction to Anand’s Unified Viscoplasticity Model (1985)

- Many metals at high temperatures experience creep and plasticity simultaneously.

- Traditional plasticity models use yield surfaces and separation rules.

- Anand proposes a unified framework to capture both phenomena without a yield condition.

- Introduces a smooth viscoplastic flow model with a single scalar resistance variable \( s \).

- Fully derived from thermodynamic principles (dissipation inequality).

- Applicable to hot working, solder behavior, and finite deformation problems.

Breakthrough Features of Anand’s Viscoplastic Model

- Plastic flow occurs at any stress level.

- No von Mises yield or loading/unloading logic.

- Enables unified creep–plasticity modeling.

- Represents resistance to inelastic flow.

- Captures hardening, softening, and recovery.

- Governs evolution in Eq. (86).

- Grounded in reduced dissipation inequality (Eq. 28).

- Ensures entropy production and realism.

- Built from stress–strain conjugacy, energy balance.

- Uses Jaumann derivatives for stress and backstress.

- Maintains frame invariance (Eqs. 63, 65–66).

- Essential for rotating frames in FEA.

- 1D model extractable from uniaxial data.

- Wang (2001) shows direct parameter fitting.

- Equations (77–86) ready for FE implementation.

Anand's model unifies physical laws, experiment, and computation in one robust viscoplastic framework.

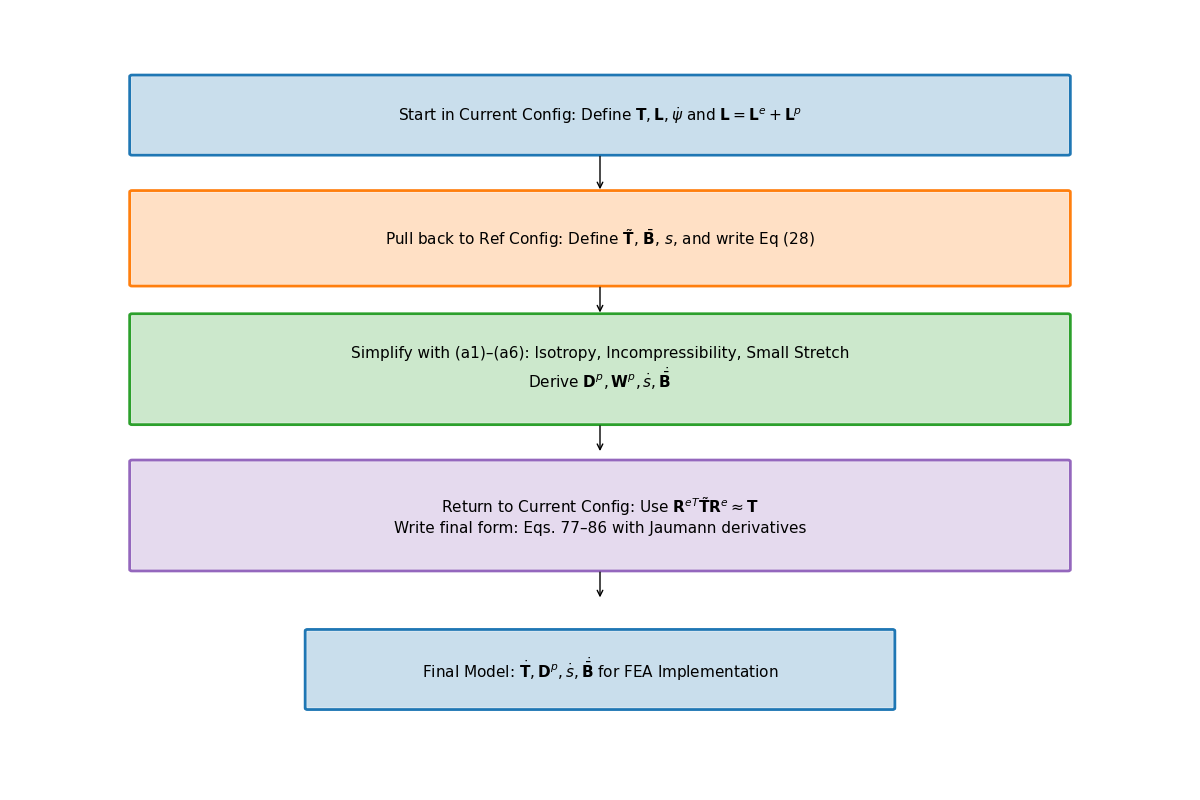

Formulation pipeline for Anand’s viscoplastic model

This flow ensures Anand’s model is thermodynamically consistent and computationally implementable.

Broad Strokes of Anand’s Unified Viscoplastic Model (1985)

1. Modeling Goal

- Unify inelastic deformation: creep + plasticity

- Avoid yield surfaces and loading/unloading rules

- Support large deformation and high temperatures

2. State Variables

\[ \{ \mathbf{T}, \theta, \mathbf{g}, \bar{\mathbf{B}}, s \} \]- Stress, temperature, and temperature gradient

- Backstress-like tensor \( \bar{\mathbf{B}} \)

- Scalar internal resistance \( s \)

3. Reference Configuration Formulation

- Switch to relaxed frame (material configuration)

- Formulate stress power and entropy production

- Arrive at dissipation inequality (Eq. 28)

️ 4. Thermodynamic Constraints

- Apply (i)-(iv): entropy, energy, heat flow laws

- Use assumptions (a1)–(a5): small elastic stretch, isotropy, incompressibility

- Restrict response functions \( \bar{\mathbf{B}}, s, \dot{s} \)

5. Simplified Constitutive Equations

- Polynomial-based evolution for \( \bar{\mathbf{B}} \) and \( s \)

- Simplified plastic flow and hardening response

6. Back to Current Configuration

- Use small elastic stretch:

- Reformulate in spatial frame for FEA compatibility

7. Final Model (Eqs. 77–86)

- Includes stress rate, flow rule, and hardening law

- Unified viscoplastic response — smooth & thermally sensitive

- Ready for implementation in FEA solvers

Viscoelasticity: Stress Relaxation and Creep

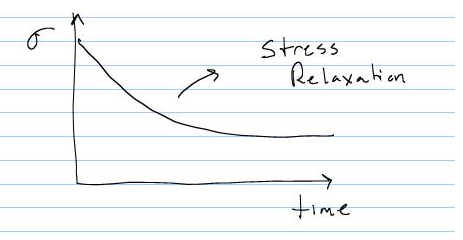

Stress Relaxation

- Occurs when strain is held constant and stress gradually decreases over time.

- Characteristic of viscoelastic materials that slowly release internal stress.

- Relevant in damping, cushioning, and biological tissues.

Graph (left): Stress drops exponentially over time.

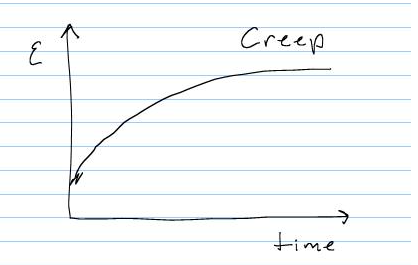

Creep

- Strain increases slowly under constant stress, even if stress does not change.

- A slow, time-dependent deformation typical in metals at high temperature or polymers.

- Appears asymptotic — strain increases more slowly over time.

Graph (right): Constant stress causes increasing strain.

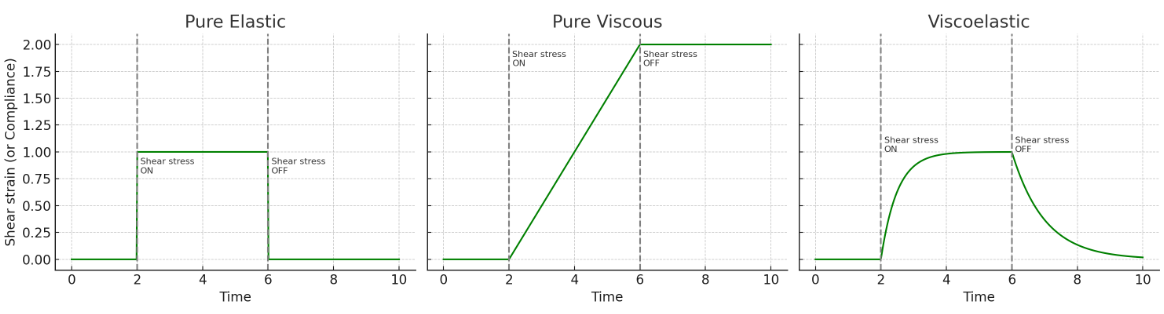

Time-Dependent Strain in Elastic, Viscous, and Viscoelastic Materials

What This Shows: The diagram below compares how materials respond to a constant applied shear stress, helping distinguish between:

- Pure Elastic: Instantaneous strain recovery once stress is removed.

- Pure Viscous: Strain grows linearly with time; stress removal halts strain, but does not reverse it.

- Viscoelastic: Initial elastic jump followed by viscous creep. After stress is removed, material shows partial recovery (stress relaxation and memory effects).

Foundational to understanding creep behavior in time-dependent models like Anand’s, where inelastic strain is smooth, history-dependent, and thermal-rate controlled.

Primary Equations of Anand Model (1D)

Stress Equation

Internal resistance to plastic flow:

Flow Equation

\[ \dot{\varepsilon}^p = A \cdot \exp\left(-\frac{Q}{RT} \right) \cdot \left[ \sinh \left( \frac{\xi \sigma}{s} \right) \right]^m \]This form enables smooth viscoplastic response based on thermal activation.

Evolution of \( s \) (isotropic resistance):

\[ \dot{s} = h_0 \left| 1 - \frac{s}{s^*} \right|^a \cdot \text{sign}\left(1 - \frac{s}{s^*} \right) \cdot \dot{\varepsilon}^p \]Saturation Value:

\[ s^* = \hat{s} \cdot \left( \frac{\dot{\varepsilon}^p}{A} \cdot \exp(Q/RT) \right)^n \]This equation governs how hardening or softening evolves with time and temperature.

In classical von Mises plasticity with isotropic hardening, the evolving yield stress is modeled as:

\[ \sigma_y = \sigma_0 + H \bar{\varepsilon}^p \]where \( \sigma_y \) represents the resistance to plastic flow.

In Anand’s model, the internal variable \( s \) plays an analogous role to \( \sigma_y \), but it evolves continuously with strain rate and temperature, eliminating the need for yield surfaces and discrete flow rules.

Material Parameters in Anand’s Viscoplastic Model

- \( A \) – Pre-exponential factor for flow rate.

- \( Q \) – Activation energy (units of energy/mol).

- \( \xi \) – Stress multiplier inside the sinh() law.

- \( m \) – Strain rate sensitivity exponent.

- \( \dot{\varepsilon}^p \) – Effective plastic strain rate.

- \( \bar{\sigma} \) – Effective (von Mises) stress.

- \( \mathbb{L} \) – Elastic stiffness tensor.

- \( \Pi \) – Stress-temperature coupling tensor.

- \( \bar{\mathbf{T}} \) – Kirchhoff stress (reference frame).

- \( \mathbf{D}, \mathbf{D}^p \) – Total and plastic strain rate tensors.

- \( s \) – Isotropic strength (scalar resistance variable).

- \( \hat{s} \) – Saturation value for \( s \).

- \( n \) – Sensitivity of \( \hat{s} \) to strain rate.

- \( h_0 \) – Hardening modulus coefficient.

- \( a \) – Exponent controlling recovery rate of \( s \).

- \( \xi_1, \xi_2 \) – Coefficients for driving terms in \( \dot{\bar{\mathbf{B}}} \).

- \( \mathbf{W}^p \) – Plastic spin tensor.

- \( b(\bar{\tau}_b) \) – Oscillation control function (for shear stability).

How Anand’s Model Unifies Creep and Plasticity

Creep-Driven Terms

Eq. (84):

\[

\dot{\bar{\varepsilon}}^p = g(\bar{\sigma}, s, \theta)

\]

Steady-state creep rate governed by stress and temperature.

Eq. (86):

\[

\dot{s} = h(\bar{\sigma}, s, \theta)\dot{\bar{\varepsilon}}^p - r(s, \theta)

\]

Captures transient creep via thermal recovery.

Hyperbolic Sine Flow Law:

\[

\dot{\bar{\varepsilon}}^p \propto \sinh\left(\frac{\xi \sigma}{s}\right)^{1/m}

\]

Models thermally activated dislocation motion.

Smooth rate-dependence:

Enables creep-like flow even at low stress without a sharp yield point.

Plasticity-Driven Terms

Internal variable \( s \):

Represents isotropic resistance; evolves with plastic strain.

Eq. (83):

\[

\mathbf{D}^p = \dot{\bar{\varepsilon}}^p \left\{ \bar{\sigma}^{-1} \mathbf{T}^r \right\}

\]

Plastic flow direction set by stress deviator.

Eq. (85):

\[

\dot{s} = \tilde{g}(\bar{\sigma}, s, \theta)

\]

Tracks hardening-like resistance from internal variable.

No explicit yield surface:

Still captures hardening and saturation as in classical models.

Interpretation of Intermediate Terms (S3 & S4)

- \(\mathbf{L}^p = x_1 \tilde{\mathbf{T}}' + \eta_1(\tilde{\mathbf{T}}' \mathbf{B} - \mathbf{B} \tilde{\mathbf{T}}')\)

- Represents viscoplastic flow direction and includes kinematic backstress effect.

- \(\dot{\mathbf{B}} = \xi_1 \tilde{\mathbf{T}}' + \xi_2 \mathbf{B}\)

- Linear evolution of internal backstress — similar to Armstrong–Frederick type models.

- \(\dot{s} = h_0 \left|1 - \frac{s}{s^*} \right|^a \cdot \text{sign}\left(1 - \frac{s}{s^*} \right) \dot{\varepsilon}^p\)

- Captures isotropic hardening/softening and saturates toward \( s^* \).

- Gives physical intuition: backstress = directional memory, \(s\) = isotropic “strength”.

- Helps map terms to graduate plasticity topics (e.g., hardening laws, associative flow).

- Facilitates debugging in FEA — parameters must align with observed behavior.

- Clarifies why Anand’s model is more than just a curve-fit: it encodes mechanics.

Thermodynamic Foundations of Anand’s Model

- \(\dot{\psi} = \frac{\partial \psi}{\partial \mathbf{E}^e} : \dot{\mathbf{E}}^e + \frac{\partial \psi}{\partial s} \dot{s}\)

- \(\eta_r = -\frac{\partial \psi}{\partial \theta}\)

- \(\Rightarrow \dot{\psi} - \mathbf{T}:\dot{\mathbf{E}}^e - \eta_r\dot{\theta} \leq 0\)

- Result: All response functions must respect the second law of thermodynamics.

- (a1) Objective stress measures (e.g., Jaumann rate)

- (a2) Isotropy in material response

- (a3) Incompressibility of plastic flow

- (a4) Free energy function is additively decomposed

- (a5) Temperature dependence enters through specific variables

- (a6) Separation of mechanical and thermal effects is approximated

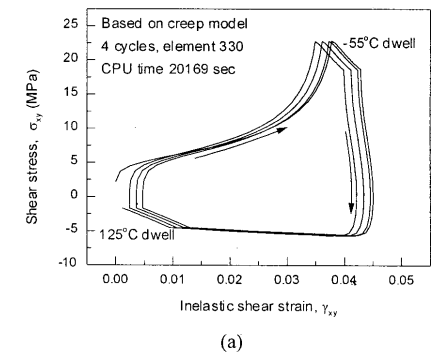

Case Study: Wang (2001)

DOI: 10.1115/1.1371781

- Applies Anand’s unified viscoplastic framework to model solder behavior.

- Focuses on thermal cycling fatigue and rate-dependent deformation.

- Demonstrates how Anand's model can be reduced and fitted from experiments.

- Helps transition the theory into engineering-scale implementation.

Anand Model Parameters for Common Solders

| Parameter | 60Sn40Pb | 62Sn36Pb2Ag | 96.5Sn3.5Ag | 97.5Pb2.5Sn |

|---|---|---|---|---|

| A (s⁻¹) | 1.49e7 | 2.30e7 | 2.23e4 | 3.25e12 |

| Q/R (K) | 10830 | 11262 | 8900 | 15583 |

| ξ | 11 | 11 | 6 | 7 |

| m | 0.303 | 0.303 | 0.182 | 0.143 |

| ŝ (MPa) | 80.42 | 80.79 | 73.81 | 72.73 |

| n | 0.0231 | 0.0212 | 0.018 | 0.00437 |

| h₀ (MPa) | 2640.75 | 4121.31 | 3321.15 | 1787.02 |

| a | 1.34 | 1.38 | 3.73 | 3.73 |

| s₀ (MPa) | 56.33 | 42.32 | 39.09 | 15.09 |

- A: Pre-exponential factor in flow rate equation.

- Q/R: Activation energy over gas constant (K).

- ξ: Stress multiplier in hyperbolic sine term.

- m: Strain-rate sensitivity exponent.

- ŝ: Saturation value of internal strength variable \( s \).

- n: Exponent in evolution equation for \( s \).

- h₀: Hardening modulus-like coefficient (drives rate of evolution).

- a: Controls the sharpness of saturation behavior in \( s \).

- s₀: Initial value of internal strength \( s \).

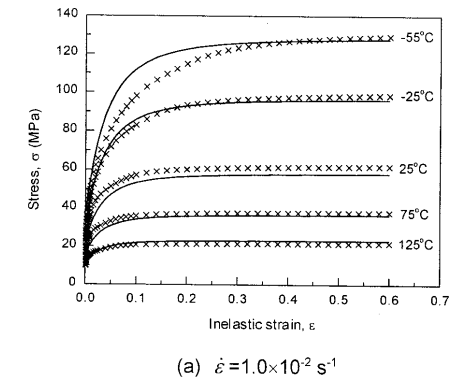

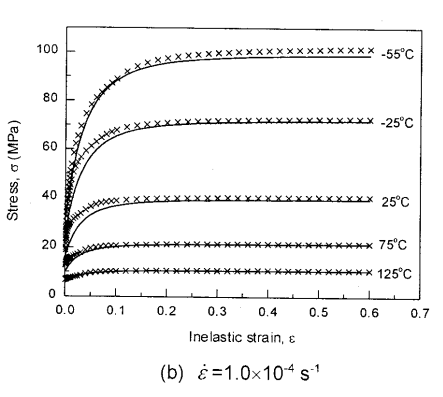

Comparing Anand Model Predictions at Two Strain Rates

- Top Graph (a): \( \dot{\varepsilon} = 10^{-2} \, \text{s}^{-1} \)

- High strain rate → higher stress

- Recovery negligible → pronounced hardening

- Bottom Graph (b): \( \dot{\varepsilon} = 10^{-4} \, \text{s}^{-1} \)

- Lower strain rate → lower stress at same strain

- Recovery and creep effects more significant

Model Accuracy: Lines = model prediction, X = experimental data

- “At lower strain rates, recovery dominates… the stress levels off early.”

- “At high strain rates, hardening dominates, and the stress grows continuously.”

Anand’s model smoothly captures strain-rate and temperature dependence of solder materials.

Anand Approximation

- FEA Ready: Smooth equations, Jaumann derivatives, and rate-dependence make it suitable for cyclic thermal loads.

- Path Dependence & Hysteresis: Anand’s model shows how evolving internal variables (like \( s \), \( \bar{\mathbf{B}} \)) naturally reproduce load history and hysteresis effects — a cornerstone of modern inelasticity.

- Path Dependence: Internal variables like \( s \), \( \bar{\mathbf{B}} \) evolve, showing hysteresis and memory effects — core ideas in inelasticity.

- Rate Sensitivity: The Anand model embodies a regularized flow rule, helping avoid ill-posedness

- Thermomechanical Coupling: Graduate models often simplify heat effects; Anand incorporates temperature-dependent recovery and strain rates realistically.

What If the Material Were Not Viscoplastic?

- No strain rate sensitivity: All curves would collapse onto a single stress–strain curve, regardless of temperature.

- Sharp yield point: Stress would remain low until a threshold is reached, then suddenly rise — no smooth buildup.

- Post-yield response: Would likely show perfectly plastic or linear hardening behavior, independent of rate.

- This behavior mirrors rate-independent J2 plasticity with isotropic hardening.

- In graduate courses, it corresponds to models with yield surfaces and flow rules only activated above yield stress.

- Contrasts Anand’s approach, where flow begins smoothly at any stress, blending creep and plasticity into one.

Common Misconceptions About the Anand Model

- “\(s\) is a fixed yield stress” — Incorrect: \(s\) evolves dynamically with strain rate and temperature.

- “This is just a plasticity model” — Not true: Anand unifies creep and plasticity in a single viscoplastic flow rule.

- “Thermal effects are secondary” — False: temperature directly drives flow via \(\exp(-Q/RT)\) and affects recovery.

- “Classical loading/unloading rules still apply” — No: There’s no yield surface, so no return mapping or activation.

- \(s\) is an internal state variable → behaves like isotropic resistance, not a hard threshold.

- Plastic flow starts at any stress — model handles low-stress creep and high-stress yielding alike.

- Thermodynamic consistency governs structure: response functions must respect dissipation inequality.

- This model is most accurate under high-T and large-deformation conditions — not just small-strain metals.

Summary of Motivation, Methods, Results, and Conclusions (Anand 1985)

- Hot working processes involve large inelastic strains, often combining creep and plasticity.

- Existing plasticity theories relied on separate yield surfaces and loading–unloading rules.

- Goal: develop a unified, thermodynamically consistent model to describe time-dependent inelastic deformation.

- Defined internal variable \( s \) to represent resistance to plastic flow.

- Formulated equations using continuum thermodynamics and the reduced dissipation inequality.

- Used objective rates (e.g., Jaumann) and decomposed velocity gradient to capture viscoplastic evolution.

- Developed a smooth flow law based on hyperbolic sine function of stress over \( s \).

- The model successfully captures steady-state and transient creep, plastic hardening, and softening.

- Yield surface and loading–unloading conditions become unnecessary.

- Formulation is compatible with finite deformation and FEA implementation.

- The Anand model offers a unified framework for viscoplasticity, blending creep and plasticity seamlessly.

- Its structure enables consistent thermodynamic modeling of large deformation in high-temperature materials.

- Laid groundwork for efficient numerical and experimental calibration in materials like solder and metals under thermal load.

Summary of Motivation, Methods, Results, and Conclusions (Wang 2001)

- Lead-free and leaded solder joints exhibit time-dependent inelastic behavior under thermal cycling.

- Full viscoplastic models are computationally expensive and hard to calibrate.

- Goal: use Anand’s unified model to efficiently capture solder behavior during cyclic loading without compromising accuracy.

- Specialized Anand model for 1D finite strain formulation with internal variable \( s \).

- Calibrated parameters using constant strain-rate tests on solder alloys.

- Simulated thermal cycling to compare Anand vs. full creep models.

- Anand model accurately captured stress-strain hysteresis behavior across temperatures and strain rates.

- Reduced computation time by ~80% compared to full creep models.

- Good agreement with experimental cyclic behavior in solder joints.

- Anand's model provides a practical and thermodynamically sound alternative to detailed creep modeling.

- It is highly suitable for engineering simulations involving thermal cycling, such as electronics reliability analysis.

Summary of Anand’s Model

The model treats rate-dependent creep and rate-independent plasticity as a single, smooth phenomenon.

Avoids arbitrary separation of strain types.

Ideal for solder and hot-working cases.

Represents average isotropic resistance to plastic flow.

Evolves with stress and temperature.

Eliminates need for complex multi-surface rules.

Captures power-law breakdown and nonlinear rate sensitivity.

Handles thermal-cycling hysteresis where traditional plasticity fails.

No need to distinguish creep from plastic experimentally.

Parameters fit to total viscoplastic strain data.

Simplifies experimental workflow.

Uses stable backward Euler integration.

No strict stability limit.

Highly effective for long-term simulations in FEA.

The Anand model unifies both creep and plasticity into one smooth viscoplastic framework, enabling predictive modeling of time-dependent deformation with thermodynamic consistency and computational efficiency.

Delete

Constitutive Equations for Isotropic Thermo-Elasto-Viscoplasticity

\[ \dot{\mathbf{T}}^r = \mathbb{L}[\mathbf{D} - \mathbf{D}^p] - \Pi \dot{\theta} \] Equation (77)

(b) Flow Rule

\[ \mathbf{D}^p = \dot{\varepsilon}^p \left\{ \frac{\mathbf{T}^r}{2 \bar{\tau}} \right\}, \quad \mathbf{W}^p = 0 \] Equation (78) \[ \dot{\varepsilon}^p = f(\bar{\tau}, s, \theta) > 0, \quad f(0, s, \theta) = 0 \] Equation (79) \[ \bar{\tau} = \left[ \tfrac{1}{2} \text{tr}(\mathbf{T}^{r2}) \right]^{1/2} \] Equation (80)

\[ \dot{s} = \tilde{f}(\bar{\tau}, s, \theta) \] Equation (81) \[ \bar{\sigma} := (\sqrt{3}) \bar{\tau}, \quad \dot{\bar{\varepsilon}}^p := \dot{\varepsilon}^p / \sqrt{3} \] Equation (82) \[ \mathbf{D}^p = \dot{\bar{\varepsilon}}^p \left\{ \bar{\sigma}^{-1} \mathbf{T}^r \right\} \] Equation (83) \[ \dot{\bar{\varepsilon}}^p = g(\bar{\sigma}, s, \theta) > 0, \quad g(0, s, \theta) = 0 \] Equation (84) \[ \dot{s} = \tilde{g}(\bar{\sigma}, s, \theta) \] Equation (85) \[ \dot{s} = h(\bar{\sigma}, s, \theta) \dot{\bar{\varepsilon}}^p - r(s, \theta) \] Equation (86)

Theoretical Stress-Strain Formulation

Stress as a Function of Plastic Strain \( \varepsilon^p \) Using the integrated model, the stress-strain relation becomes: \[ \sigma(\varepsilon^p) = \sigma^* - (\sigma^* - \sigma_0)(1 - \exp(-ch_0 (\varepsilon^p)^{1-a})) \]

- \( \sigma_0 \): initial yield stress

- \( \sigma^* \): saturation stress (UTS)

- \( c, h_0, a \): shape and evolution constants